Case Studies

PALMER ENGINEERING & FORENSICS, LLC has been providing high-quality failure analysis and engineering investigations to the legal and insurance industries, as well as commercial, industrial, and municipal clients throughout the United States and internationally, since 2009. In our extensive history of helping our clients understand the root causes of failure and recover from losses, we have collected an extensive series of case studies. We encourage you to read through a few of our example case studies to learn more about our multidisciplinary engineering and forensics firm.

Electrical Case Studies

Electricity is a truly remarkable and ubiquitous source of energy that we encounter in nearly every aspect of our lives. Unfortunately, if that energy is not properly controlled—such as in the cases of equipment malfunction, failure to comply with codes, inadequate compliance with safety procedures, or other issues—the energy can damage people and property.

Here are just a few examples of cases where an electrical failure had serious negative consequences. Note that many of our Fire Case Studies also involve electrical failures.

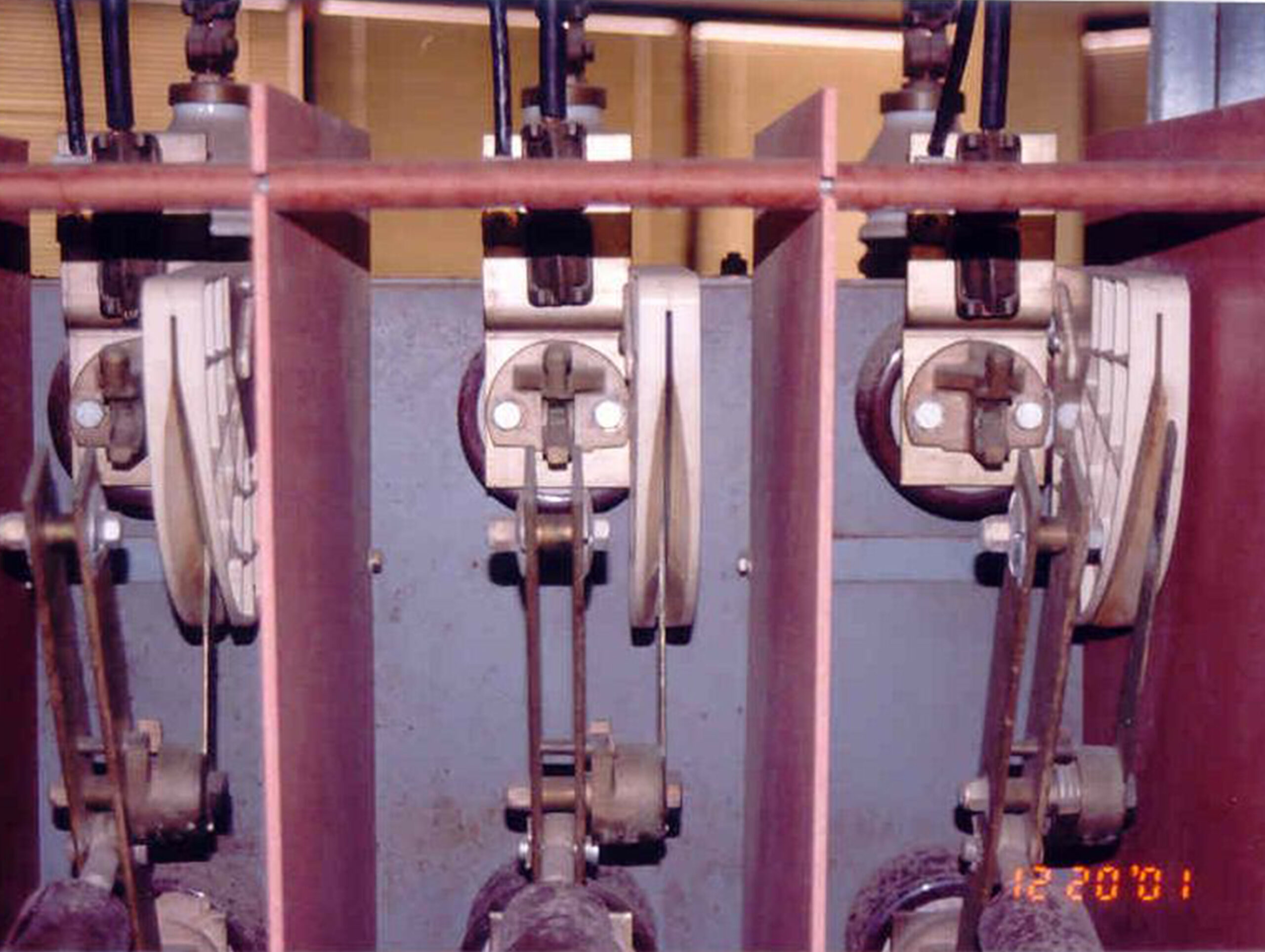

Load Circuit Interrupter

A load circuit interrupter (LCI) like this one was installed in an industrial facility to power a transformer at 4160 volts. The transformer failed and needed to be replaced. The electrician turned off the power to the transformer by opening the LCI and locking the handle into the open position.

Unfortunately, due to a design defect, part of the switch contacts remained engaged, so one of the leads remained energized at over 2,000 volts. While replacing the transformer, the electrician made contact with the energized lead and was electrocuted.

Squirrel vs. Sub-station

An unfortunately curious squirrel was exploring the energized conductors in this substation that serves a small town in the North Midwest of the US. When its body spanned an electrical insulator between the ground and the energized conductor, it initiated an electrical arc.

If the substation protection had been working properly, a circuit breaker would have opened, and the only damage sustained would have been to the squirrel. Maintenance personnel, however, had disabled the automatic protection while doing maintenance and forgot to re-enable it. The error resulted in hundreds of thousands of dollars in damage and left a town without power for hours.

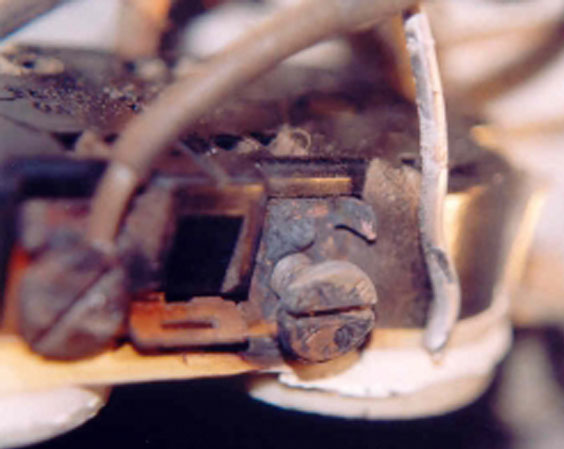

Aluminum Connectivity

Aluminum wiring has been known since the 1970s to lead to connectivity problems, overheating, and even fires. This photo illustrates the phenomenon: The aluminum wire was screwed to an electrical outlet, but over time, the wire became loose. The loose connection resulted in extreme heating at the receptacle. Fortunately for the homeowner, the outlet stopped working before a fire could happen. Other aluminum wiring failures have had much more catastrophic results.

Millions in Revenue Lost

The crack in this electrical bushing, which was part of the 13.8 kV power distribution system for a large resort hotel, was not observed by those assembling the system. The crack remained undetected until a major rainstorm filled the manhole with water and bridged the path to the ground within the bushing, creating a system fault that spread to damage other equipment in the same manhole.

The improper procedures of the maintenance personnel caused additional damage, and the hotel was out of service for three days while repairs were made. Unfortunately, the hotel was at maximum occupancy at the time of the incident, so the business interruption cost the hotel millions.

Code Violation Results in Death

When an electrical lineman was working on these 13.8 kV connections in a substation, he thought the cubicle was de-energized like the others were in the row of cubicles. However, a less common configuration was present, and no signage was there to warn him of the irregularity (as required by code). Consequently, an arc flash occurred, which ultimately killed the lineman.

Tanning Bed & Smoke Damage

This bundle of wires formed an electrical connection for a large number of lights in the top half of a tanning bed. Maintenance personnel did not fully insert the connector when they completed their work on the bed, and the connection severely overheated and generated a very large quantity of smoke. While the failure did not result in a full-fledged fire, the smoke damage was extensive throughout the facility and led to considerable business interruptions while clean-up and repairs were being made.

Accidental Power

This indoor substation was in poor repair and severely outdated when maintenance personnel entered it to clean up debris from the room. They believed the entire substation to be de-energized, and no signage or warnings were present to advise them that the leads into the facility and the blades on the disconnect associated with the incoming power were still energized. Consequently, one of the maintenance workers, in trying to remove a chain that was tangled in the overhead bus work, accidentally initiated an arc flash and was fatally burned.

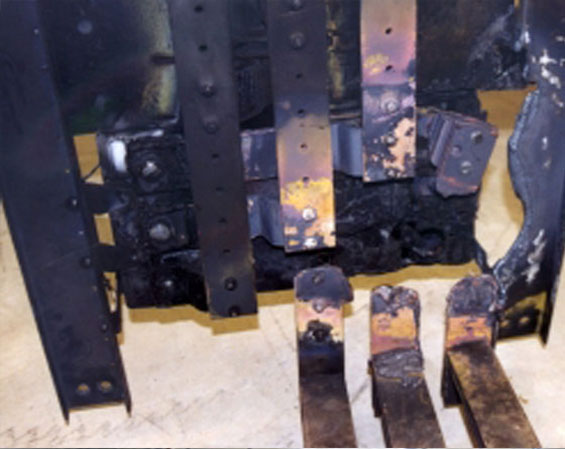

Metal Shavings Lead to a Melted Switchboard

An electrician was drilling a hole in a de-energized vertical bus bar that was part of this commercial switchboard. Unfortunately, he did not realize that the work he was doing posed a hazard, and when a metal shaving from the drill fell onto the energized bus bars below, an arc flash occurred, melting a considerable amount of copper and destroying the switchboard.

Fire Case Studies

When too much energy is put in the wrong place, unfortunate events can occur. Here are a few circumstances where fires or explosions occurred because a fuel supply and a heat source were too close together. Heat sources can be unintentional, such as an electrical failure, or intentional, such as a pilot light. There are also several examples of fire case studies involving electricity in our electrical case studies section.

From Drying Clothes to Starting Fire

When the owner of this dryer started drying her clothes, she would take her dog out for a walk (the dog couldn’t stand the noise). She did not know that the bearing in the dryer had worn out and that the bearing support was cutting into the shaft. Ultimately, she came back from one of her walks to find the house on fire because the shaft had worn clear through and broken, resulting in the drum making contact with the electrical heating coils behind it. The electrical short generated excess heat and started a fire.

Fire Results in Water Loss

When a bathroom vent fan failed catastrophically, it dripped burning plastic from its cover. The burning plastic ignited the toilet lid cover and the rug below the toilet. The fire might have spread catastrophically, but the heat of the fire cracked the toilet tank, which then quenched the fire. Consequently, the event turned out to be a water loss more than a fire loss because the toilet supply line continued to discharge water for hours before the homeowners returned.

Propane Leak Causes Damage

Most of the connections in the propane system of this house were put together properly. Unfortunately, one that was buried just outside the house was not tightened sufficiently by the installer, and settlement in the soil around the house caused the connection to break free.

The gas leaking into the soil migrated through the penetrations in the basement wall and accumulated in the basement until it ignited when the boiler fired. The damage to the home was quite extensive. Consequently, the event turned out to be a water loss more than a fire loss.

Toilet vs. Power Plant

The day started out with a backed-up toilet and ended with a catastrophic explosion of this 450 MW power plant (depicted here after reconstruction). Unfortunately, while the plumber was trying to resolve the drain stoppage, a sump pump turned on and dumped a significant quantity of untreated sewage onto the fuel safety control system computer and interfaces.

The maintenance team that was assembled to remediate the mess was not trained on the equipment and did not lock out the fuel gas. A series of errors on the part of the maintenance team resulted in signals being sent to inadvertently open the main gas valve, and the boiler full of natural gas exploded a short time later.

Improper Wiring Protection Leads to Fire

In the course of renovating a basement room, an electrician installed electrical wiring just above the I-beam shown here on the surface of a wooden support plate. The wiring was not properly protected from penetration as required by the National Electrical Code, and when the drywall contractor was installing the sheetrock, he drove a screw right through the electrical cable. When the electrician came back later and turned on the circuit breaker, the resultant short circuit started a fire.

Bagel Blaze

The man who lived in this townhome left his bagel in the toaster as he rushed out the door on his way to work. Unfortunately, a mechanical defect in the toaster prevented it from “popping up” when the bagel was toasted, and it continued to be heated until it ignited. The resultant fire created this classic “v-pattern” on the kitchen wall.

Sewing Machine Autopilot Fails

This high-end electric sewing machine had numerous features, including the ability to operate virtually unattended. Fortunately, the owner was in the same room when the power supply failed catastrophically and ignited a small fire. She had a fire extinguisher nearby and put the fire out before it spread to the large piles of fabric that were nearby.

Cash Register Kills Fish

At some point during the middle of the night, an internal component of a cash register catastrophically failed, igniting a piece of plastic mounted to the circuit board. The fire then spread to the plastic housing of the register and out to the counter. The fire ultimately burned itself out, but not before producing enough smoke to kill the store’s entire inventory of tropical fish.

Mechanical Case Studies

Mechanical engineering encompasses a wide range of topics, including vehicle accident reconstruction, biomechanics, plumbing, fires and explosions, HVAC and other gas systems, product defects, and more. Following are a few examples of mechanical related failures we have had the opportunity to investigate.The complex infrastructure in buildings, including foundations, roofs, and plumbing, is not intended to move significantly. When they do move or fail, the consequences can be dire. Here are examples of civil and structural failures and what can be done about them.

Leaking Shower Mystery

Our forensic civil engineer was called to investigate the cause and origin of leaks in some fifty-five custom-made showers in a new downtown Denver hotel. Reportedly, all of the showers had been constructed by the same subcontractor.

Destructive testing revealed that at least one of the origins of the leaks was related to the improper installation of a waterproofing membrane at the shower drainage flange. Our civil engineer’s hands-on experience in overseeing the construction of custom showers allowed the problem to be pinpointed quickly through the identification and initial targeting of one of the most likely causes and origins.

Restoration of 130-Year-Old Log Church

Unfortunately, this 130-year-old log church in southwestern Montana was converted into a hunting lodge before major structural problems were addressed. A few years after its interior renovation, the north wall began to collapse, and a portion of the floors was more than ten inches out of level, requiring immediate action to salvage the building.

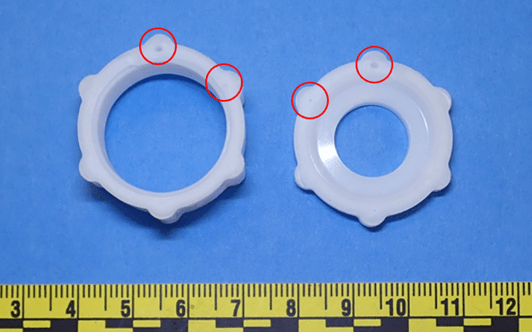

Widespread Toilet Supply Line Failure

Toilet supply lines are connected to the toilet fill valve with a coupling nut. In many cases, particularly residential cases, the coupling nut is made of plastic. A particular coupling nut design has been the subject of more than 20 separate cases at Palmer Engineering & Forensics. The nut is an injection molded part where plastic is heated to a viscous liquid and injected into a mold. The mold is then cooled, but the cooling process is performed too quickly which causes a significant temperature gradient through the thickness of the nut. Effectively, the outer surfaces of the nut cool to a solid while the interior of the nut is still liquid, which causes voids to occur within the nut. After 2 – 5 years of service, the voids act as crack initiation sites which results in catastrophic failure of the nut and, in turn, a water loss in the home.

Civil & Structural Case Studies

The complex infrastructure in buildings, including foundations, roofs, and plumbing, is not intended to move significantly. When they do move or fail, the consequences can be dire. Here are examples of civil and structural failures and what can be done about them.

Leaking Shower Mystery

Our forensic civil engineer was called to investigate the cause and origin of leaks in some fifty-five custom-made showers in a new downtown Denver hotel. Reportedly, all of the showers had been constructed by the same subcontractor.

Destructive testing revealed that at least one of the origins of the leaks was related to the improper installation of a waterproofing membrane at the shower drainage flange. Our civil engineer’s hands-on experience in overseeing the construction of custom showers allowed the problem to be pinpointed quickly through the identification and initial targeting of one of the most likely causes and origins.

Restoration of 130-Year-Old Log Church

Unfortunately, this 130-year-old log church in southwestern Montana was converted into a hunting lodge before major structural problems were addressed. A few years after its interior renovation, the north wall began to collapse, and a portion of the floors was more than ten inches out of level, requiring immediate action to salvage the building.